We shoulder responsibilities for sustainability

by incorporating ESG foundations in our DNA at Ennostar

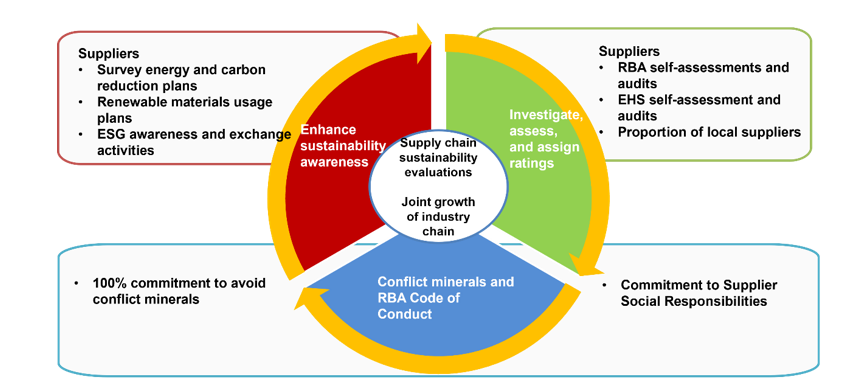

The Group mainly procures raw materials, components, equipment, and engineering services. In 2023, we worked with more than 3,616 suppliers around the globe. To ensure that suppliers adhere to our sustainability requirements, all of our suppliers across all procurement categories have to sign a Commitment to Supplier Social Responsibilities and undergo related risk evaluation mechanisms.

The Group is a professional OEM manufacturer with products encompassing epi wafers, chips, packaging, SMT, and compound semiconductors. Our main raw materials and components include sapphire substrates, gallium arsenide substrates, special gases, metals, brackets, and LED motherboards. All key materials and components are purchased from more than two suppliers to maintain procurement flexibility and reduce risks from over-concentration of raw materials.

Number of suppliers Management Organization

|

Domestic |

3,382 |

|

Overseas |

234 |

To prevent sudden supplier closures from affecting material supplies and to reduce supply shortage risks from extreme climate and major natural disasters, we conduct periodic and non-periodic checks on supplier operations and finances, diversify material sources, and keep informed of geographical distributions of supplier production lines to keep abreast of supply chain conditions. We have also established an emergency response team and emergency response processes for handling of abnormal supplier incidents. We conduct regular situational drills to ensure that we are adopting the most appropriate prevention measures for supply chain risk management, thereby protecting stakeholder interests from operational hazards.

In terms of supplier risk assessments, the Group has established different risk assessment processes and assessment items based on the different business models adopted by new suppliers, existing suppliers, and our subsidiaries. All collaborating companies are required to sign an “Integrity Commitment Statement.” All Group subsidiaries will gradually incorporate sustainability concepts in risk assessment items.

√ None of our suppliers were faced with major human rights risks related to freedom of association, collective bargaining, use of child labor, or forced or compulsory labor in 2023.

We ensure that all Group products do not use or contain conflict minerals (including gold, tantalum, tungsten, or tin) from the Democratic Republic of Congo (DRC) or surrounding regions controlled by military groups or non-governmental/illegal military factions. All Group subsidiaries implement responsible procurement and we established and publicly posted the Group “Conflict Minerals Management Declaration” in 2023. We conduct reasonable due diligence on suppliers and all qualified suppliers are required to sign the “Commitment of Suppliers to Prohibit Use of Conflict Minerals.” We completed surveys of 100% commitment to non-use of conflict minerals in accordance with OECD RMI organizational requirements, and work with our supplier partners to fulfill our social and environmental sustainability commitments.

All suppliers of metal plating used in our production processes follow the spirit of the OECD and RMI organizational procedures. Each year, we complete due diligence procedures and conflict mineral surveys; collect CMRT, EMRT, and PRT reports; and also provide CMRT, EMRT, and PRT reports in accordance with customer requirements to ensure that 100% of products used by our customers do not contain conflict minerals.

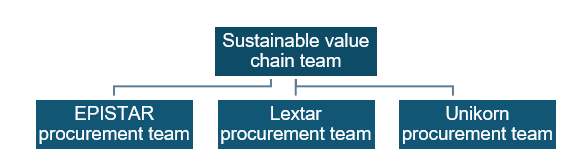

In future, we hope to continue working with our supply chain partners to develop carbon reduction technologies, achieve carbon reduction benefits, strengthen green supply chain developments, and enhance supply chain resilience. We continue to improve our social responsibilities associated with procurement to ensure that we do not provide any products using conflict minerals, to improve carbon reduction capabilities associated with our SBTi commitments, and to become an industrial sustainability value chain benchmark. The sustainability value chain team adhered to these strategies when planning our three main axes and five-year plan:

Three main axes

- Sustainability awareness: Ensure that suppliers adhere to government environmental protection laws and EHS requirements

- Supplier rankings: Prompt suppliers to conduct carbon inventories and implement carbon reduction plans

- RBA: Require suppliers to comply with regulations and policies for conflict minerals, as well as RBA guidelines

Five-year plan